About Us

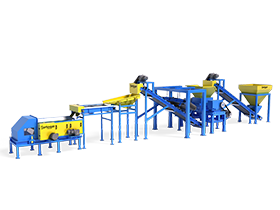

Your Sortinger, Your Solution

Precise sorting capabilities, allowing effortless selection

“Sortinger believes that professional sorting technology is the key to a sustainable future.”

Brand story

Innovative sorting technology, bestowing the opportunity for rebirth

Change, starts from Sortinger

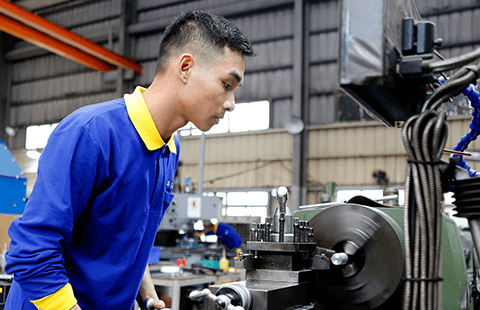

The company first operated under the name Nian Hung and manufactured strong magnets, tube magnet, and grate magnet. To keep up with the needs of our clients, we started the R&D as well as manufacture of magnetic separators. In 2019, the company underwent a rebranding process and changed its name to Sortinger Magnetic Separation Industrial Co., Ltd. Today, Sortinger, along with clients from various industries such as recycling, food, plastic and rubber materials, medicine, chemicals, electronics, and construction, are working toward the vision of a more environmentally friendly planet.

We wish for every one of our magnetic separators to function as a distinct sorting expert. As our products are gradually distributed to all corners of the world, not only do we advocate the concept of extended material use, but our clients are provided with efficient and convenient sorting services.

The “er” from “Sortinger”, acts as a form self-encouragement, reminding ourselves of the need to seek continuous improvement and innovation for new sorting technology. We shall dedicate our efforts to making sure recycling becomes an easy and profitable act; creating opportunity for all things to be reborn and reused.

Our History

2020

New Brand - Sortinger

Established a new brand "Sortinger" to serve the global market.

2019

Coped with 5G era and environmental protection trend, changed name into Nian Hung Magnetic Industrial Co., Ltd., and obtained 16 patents.

2010

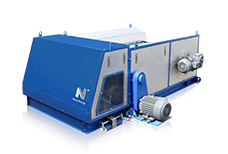

Eddy Current Separator

Developed the first Eddy Current Separator in Taiwan; devoted into the field of “recycling sorting machine.”

2001

2001-2003

Expended operation scale with Nien-Far Techonology Co., Ltd. & Shanghai Nian Hung Magnet Industrial Co., Ltd.

1999

Marched into Chinese market and found Shanghai Niean-Far Technology Co., Ltd. at the next year.

1995

Uphold the sustainability concept, put our hands to the development of magnetic separators.

1982

Nian Hung

Nian Hung Electric Industrial Co., Ltd. was established at Douliu Industrial Park, a manufacturer specializing in the production of permanent magnets.

Advantage

Precise sorting, profit from recycling

Sortinger’s magnetic separators are applicable to the sorting of liquids, as well as solids of different sizes, including material granules ranging from millimeters to micrometers and even nanometers in length. This enables clients to profit from recycling, therefore encourages them to take part in the recycling of materials, creating a zero waste production chain.

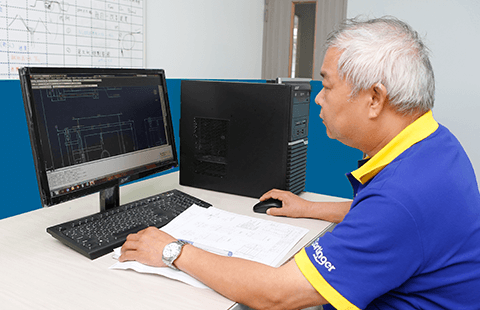

A fixed contact, saving time and effort

Sortinger Magnetic Separation Industrial Co., Ltd. provides its services via a single contact. From presenting technical information, offering procurement recommendations to overall site planning, our team of experts are able to gain the trust of our clients, and eliminate costs derived from repetitive communication, as well as help our clients to quickly enter the production stage.

Extensive experience and customized solutions

By being familiar with the characteristics of a whole variety of materials and possessing the ability to integrate a multitude of sorting technologies, we are able to provide our clients with resource sorting solutions that best fit their needs. Our high sorting rates ensure that clients maintain their competitive edge. Sortinger has extensive cooperation experience with many fields, including recycling, food, plastic and rubber materials, medicine, chemicals, electronics, and construction. Moreover, we also offer assistance when it comes to market development.

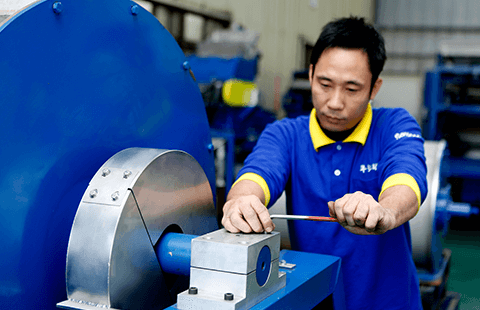

Continuous innovation for extended material life span.

Not only do we constantly engage in the development of new sorting technology, but also actively work toward optimizing existing technology, in turn, establishing a solid foundation for the recycling industry technology and achieving extended material life span.