Share

when and where

2020/1/16(Thu) - 1/20(Mon)

Bombay Exhibition Centre (Bombay Exhibition Centre, N.S.E. Complex, Goregaon(East), Mumbai, India)

Organizer

THE ALL INDIA PLASTICS MANUFACTURERS’ ASSOCIATION(AIPMA)

Exhibition introduction

Market characteristics: India is the second most populous country in the world with a population of 1.3 billion, second only to China.

Last introduction: As one of the top 10 professional plastics exhibitions in the global plastics industry, the last India Plastics Exhibition covers an area of 100,000 square meters. The exhibitors have 1,500 exhibitors from 25 countries and 250,000 professional visitors. Exhibitors and visitors from Germany, UK, France, Portugal, Italy, USA, China, Taiwan, Korea, Japan, Singapore, Austria, Bangladesh, Nepal, Bhutan, Myanmar, Thailand, Sri Lanka, United Arab Emirates, Oman, Saudi Arabia, Nigeria More than 30 countries including South Africa, Uganda and Tanzania.

Market introduction: India's plastic production, from an annual output of 7.5 million tons to an annual output of 15 million tons, India will soon become the world's third largest plastic consumer, during which the plastic mold industry will be grand. The huge increase in polymer consumption in the Indian market will make India rank second only to the polymer consumer market after the US and China in the next three years. The market investment will reach Rs 2,500 crore, or about 208.3 billion yuan. India's population has exceeded 1.3 billion, the rapid growth of the automotive industry, the growth in demand for household appliances and consumer goods, and the development of the food and printing and packaging industries have all contributed to the increasing demand for plastics in the country, whether in the raw materials or plastic processing industries. Long-term flourish.

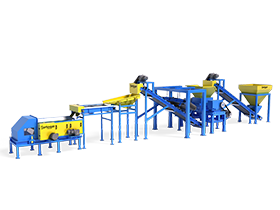

There is a large demand for plastic machinery in India before the plastic machinery market, for example: the minimum demand for injection molding machines is 25,000 units, the demand for blow molding machines is 5,000 units, and the demand for extruders is 10,000 units. Foreign investment: India has a very good foreign direct investment environment, overall economic stability, market liberalization, and expanding economic and trade links, making India an attractive investment destination for companies around the world.

As India's economic globalization deepens, India is eager to develop export markets while developing its domestic market. India's plastics, which are supported by the global market, have experienced a lot of trade sweetness. According to the calculation of the Indian government, more than 100 plastic processing plants and “plastic parks” will be built in the next few years to improve the technical content of plastic exhibits. The Indian plastics that travel around the world are more dynamic after integration and upgrading.

The Indian plastics industry is performing well, driven by the use of plastics and the health needs of the end-user industry. India has 17 major polymer producers with substantial investments. The plastics industry of 1.02 million rupees is growing at a compound annual growth rate of about 20% (annual compound growth rate).

The plastics industry will hit Rs 17,000. India has about 55,000 manufacturers including large, small and tiny departments. The Indian plastics industry is spread across the country and employs approximately 4 million people. As plastic demand grows, India will become the third largest consumer of plastics.

The plastics industry is growing rapidly. The innovative application of “India” and the trend of agricultural plastics are promising: India’s plastics industry has great potential, and the market growth rate is twice the GDP growth rate. In the next few years, India’s GDP growth rate is estimated to reach 7.5%. That is, the plastics market can grow by 15%.

With the popularization of plastics in infrastructure, medical supplies, and agriculture, the Indian plastics market is expected to have a rapid growth period. Modern people's lives are almost inseparable from plastics, such as clothes, construction, furniture, automobiles, electrical appliances, household items, agriculture, gardening, irrigation, packaging, medical equipment, etc., all kinds of food and clothing will use plastic products. At present, India's plastics industry is one of the best export potential of developing countries. The Indian plastics industry has more than 30,000 processing plants and 2,000 exporters, with a total employment of 400,000, of which 85% to 90%. The industry is small and medium enterprises. The main products include plastic raw materials, extrusion molded products, polyester film, plastic sheet, molded soft luggage items, writing instruments, plastic woven bags and packaging bags, PVC leather and plastic cloth, packaging materials, consumer goods, bathroom accessories, Electrical accessories, laboratories, medical and surgical supplies and travel supplies.

Small passenger cars and electronic products drive the "India" rubber and plastics machine to swell: the main settlements of the Indian rubber and plastics machinery industry include: Pune in Maharashtra; Ahmedabad in Gujarat; Coimbatore and Chennai in Tamil Nadu; Bangalore in the state of Karnataka. Among them, South India Karnataka is regarded as the main area of Indian tool machinery, and also a major rubber production town. According to the organizer, the All India Plastics Industry Association (AIPMA) pointed out that the Indian plastic machinery market has huge demand, injection molding machines and blow molding machines. With the extruder is a large demand.